Advanced Crushing Solutions Underway for Indonesia

At STLTG, our commitment to delivering world-class heavy machinery extends from initial design to rigorous manufacturing and beyond. We are excited to announce a significant project for the Indonesian market, where a customized STLTG crushing plant is currently in production, set to bolster Indonesia’s burgeoning infrastructure and aggregate industries. This initiative underscores STLTG’s dedication to precision engineering and tailored solutions for our global partners.

Indonesia is a dynamic market experiencing robust economic expansion and extensive infrastructure development. The demand for high-quality aggregates for road construction, urban expansion, and building materials is at an all-time high. Our Indonesian client required a reliable, high-capacity, and specifically configured crushing solution to efficiently process diverse raw materials. STLTG’s team engaged in deep consultation, understanding their unique operational landscape, material characteristics, and production targets to engineer the optimal plant.

The STLTG: Quality and Precision in Every Detail

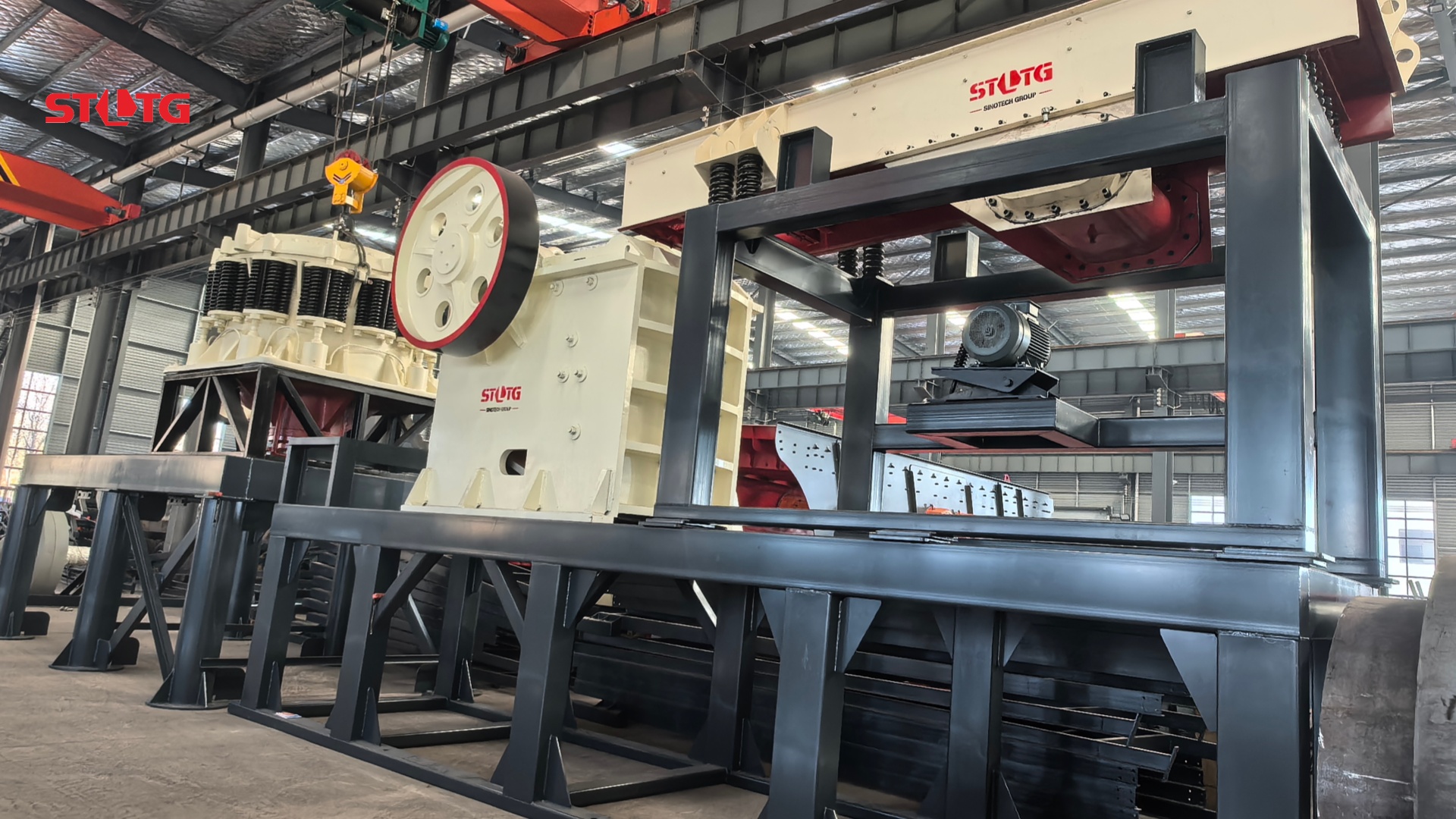

Our state-of-the-art manufacturing facility is currently bringing this bespoke crushing solution to life. The STLTG difference lies in our unwavering commitment to:

- Customized Design & Engineering: Each component of the crushing plant – from the robust primary Jaw Crusher to the high-efficiency Cone Crusher – is being meticulously crafted to meet the client’s precise requirements and the demanding conditions of the Indonesian environment. Our engineers have optimized the layout and individual machine specifications for maximum throughput and material quality.

- Superior Material Selection: We utilize only premium-grade, high-strength alloys and wear-resistant components, ensuring exceptional durability and a prolonged operational lifespan. This critical step minimizes future maintenance needs and guarantees sustained performance.

- Advanced Manufacturing Processes: Leveraging cutting-edge fabrication, welding, and assembly techniques, our skilled technicians meticulously construct each unit. Every weld, every joint, and every fitment undergoes stringent checks to adhere to STLTG’s exacting quality benchmarks and international standards.

- Rigorous Pre-Shipment Quality Control: Before any component leaves our factory, it undergoes a comprehensive series of quality assurance tests. This includes material integrity verification, dimensional accuracy checks, functional testing of individual modules, and a final inspection of the entire assembled system (where feasible for modular units). Our commitment to “Quality & Durability Guaranteed” ensures that only fully verified and top-performing equipment is prepared for shipment.

Partner with STLTG for Your Next Project

Discover how STLTG’s expertise in heavy machinery manufacturing and customized solutions can benefit your operations. Contact us today to discuss your specific project needs and explore how we can contribute to your success.