STLTG Asphalt Mixing Plant

Our asphalt plants are integral to any project that involves creating or maintaining pavements, providing essential materials efficiently, accurately, and affordably.

From asphalt buyers to producers: High-quality, portable, and eco-friendly asphalt plants. Get your customized solution today

Mixing Capacity

750-5000 kg/batch

Output Capacity

40-320t/h

Why Switch to Your Own Asphalt Plant?

The math is simple: Every ton of asphalt purchased from third-party suppliers includes markups for transport, middlemen, and profit margins. By producing in-house with our plants, you reclaim those costs—typically achieving full ROI within 6-12 months.

But savings are just the start. Imagine guaranteeing consistent quality for every project by controlling mix designs onsite. Picture bidding more competitively knowing your material costs are 20-30% lower than rivals still relying on suppliers.

STLTG never facing another delay because a supplier missed a delivery. Our clients—from highway contractors in Nigeria to material wholesalers in Chile—use these plants to transform from price-takers to market leaders.

Popular Asphalt Mixing Plant Types

An asphalt plant is a facility designed to produce asphalt mixtures, which are essential for constructing and maintaining roads, highways, parking lots, and other pavement surfaces. These plants mix aggregates (like sand, gravel, or crushed stone) with bitumen (a petroleum product) to create asphalt concrete.

Here are some popular STLTG asphalt plant that sells best:

Mobile Asphalt Plant

Mobile asphalt plants are particularly well-suited for mountainous regions and confined spaces because of their modular design, which allows them to be mounted on vehicle chassis for easy relocation. Additionally, for long-distance road construction projects that involve narrower paths, portable hot mix plants—especially the integrated types—offer distinct advantages like quick transportation, simple setup, and fast production restarts.

Quick View:

Models: LBQY60-LBQY160

Hopper Capacity: 4×4.5m-5x8m³

Diesel Engineering Power: 200- 400KW

Output Capacity: 60-160t/h

For more rated voltage range and capacity, welcome to send inquiry for details.

Stationary Asphalt Plant

Stationary asphalt plants are beneficial for large, ongoing construction projects due to their capacity, quality control, and overall efficiency, making them a preferred choice for contractors involved in significant paving jobs.

Quick View:

Models: LB1000-LB4000

Hopper Capacity: 4×4.5 m³-6×15 m³

Output Capacity: 80–320t/h

For more rated voltage range and capacity, welcome to send inquiry for details.

Simple Asphalt Plant

Simple asphalt mixing plants typically have lower initial investment costs compared to more advanced and complex plants. They are a cost-effective option, especially for small-scale projects or those with budget constraints.

Quick View:

Models: LY10-LY20

Mixing Drum Capacity: 1500L-3000L

Output Capacity: 10–20t/h

For more rated voltage range and capacity, welcome to send inquiry for details.

WHAT MAKES US SPECIAL?

80+

Successful Projects

100%

Satisfied Customers

90+

Exported Countries

STLTG Asphalt Plant Specification

Technical performance parameters of main parts of LB series asphalt mixing equipment

| Parameters Model | LB-1000 | LB-1500 | LB-2000 | LB-3000 | LB-4000 | LB-5000 |

| Width(mm)of feeder belt | 500 | 500 | 600 | 650 | 650 | 800 |

| Conveying capability (t/h)(adjustable)of feeder | 60-180 | 60-200 | 60-200 | 60-360 | 60-360 | 60-500 |

| Number of feeder hoppers(Pcs.) | 4 | 5 | 5 | 6 | 6 | 6 |

| Volume of skeletal material hopper of feeder | 4/32m³ | 5/40m³ | 5/40m³ | 6/60m³ | 6/60m³ | 6/90m³ |

| Width of belt conveyor | 500 | 650 | 650 | 800 | 800 | 800 |

| Diameter of heating cylinder(m) | 1.65 | 1.85 | 2.2 | 2.5 | 2.75 | 2.8 |

| Length(m)of heating cylinder | 7 | 7.5 | 9.1 | 9.5 | 10.2 | 12 |

| Productivity (t/h)of heating cylinder (water content 5%) | 100 | 140 | 180 | 265 | 380 | 480 |

| Lifting capacity(t/h)of hot material elevator | 120 | 140 | 180 | 265 | 340 | 450 |

| Productivity(un)of hot material vibrating screen | 120 | 140 | 180 | 260 | 340 | 450 |

| Yield(kg)of each mixing pot | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 |

| Mixing time(s)(adjustable) | 30-60 | 30-60 | 30-60 | 30-60 | 30-60 | 30-60 |

| Volume of mixed material bin | 40Underlaid | 40Underlaid | 60Underlaid | 100Underlaid | 100Underlaid | 100Underlaid |

| Unloading height(m)of mixed material bin | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | 4.0 |

STLTG Asphalt Plant Solutions for Your Business Type

For Asphalt Buyers (Become a Producer)

If your business currently purchases asphalt for paving or patchwork, you’re leaving money on the table.

Our compact batch plants (80-160 TPH) let municipalities, construction firms, and industrial facilities produce their own asphalt at up to 30% lower cost per ton.

With automated controls and pre-engineered modules, even first-time operators can produce specification-perfect mixes after just 3 days of training.

Worried about space? Our mobile units fit on half-acre sites and relocate as projects shift.

Hesitant about maintenance? Our IoT-enabled plants self-diagnose 85% of issues, with spare parts guaranteed to ship within 48 hours worldwide.

More advantages of owning your own asphalt plant:

Quality You Can Control

- Supplier asphalt often varies in grade, forcing compromises on projects. With your own plant:

- Adjust mix designs on the fly (perfect for polymer-modified or recycled asphalt).

- Test batches in your onsite lab before production.

- Reject 0% of deliveries (because you control every step).

Turn Excess Capacity into Revenue

- Once your core needs are met, sell surplus asphalt to:

- Local contractors (at 15% below market rates—still profitable for you).

- Municipalities needing small-batch specialty mixes.

- Client Story: A Nigerian construction firm now covers 100% of their plant costs by selling just 20% of their output.

For Asphalt Sellers (Expand Your Profits)

As a material reseller, your profitability hinges on supplier pricing—until now. Forward-thinking distributors from Vietnam to Peru are using our plants to vertically integrate, buying raw materials at bulk rates and producing higher-margin asphalt blends under their own brand.

Offer specialty mixes (polymer-modified, warm-mix) competitors can’t source. Lock in municipal contracts by guaranteeing supply during peak seasons.

We even support white-label configurations—your branding, your quality control, your customer loyalty. Financing options allow you to cash-flow the plant with production profits.

More advantages of owning your own asphalt plant:

Win More Bids with Guaranteed Supply

- Municipal and large-scale buyers prioritize suppliers who:

- Can’t be disrupted by external shortages (like 2022’s bitumen crisis).

- Offer just-in-time production (store raw materials, produce to order).

- Case Study: A Brazilian distributor landed a $4.2M airport contract by proving they owned production capacity.

Future-Proof Against Market Shocks

- When oil prices spike or tariffs hit, you’re insulated because:

- You control input costs (buy bitumen futures if needed).

- Competitors relying on imports get squeezed; you gain market share.

For Road Contractors (Ensure Supply & Save)

While competitors sell bulky, fixed installations requiring months of setup, our German-engineered modular plants deliver faster deployment, smarter operation, and greener production.

The secret? Patented vibration-resistant modules assemble like LEGO blocks—no poured foundations needed. Microprocessor controls automatically adjust mix parameters for humidity and material variability, reducing waste by up to 15%.

Unlike traditional drum plants emitting black smoke, our closed-loop system captures 99.2% of particulates, meeting California Air Resources Board (CARB) standards.

For remote sites, hybrid power options (diesel/solar/grid) keep you running. This isn’t just machinery; it’s your competitive edge poured into steel.

More advantages of owning your own asphalt plant:

Mobile Plants = Competitive Moats

- Our rapid-relocation systems let you:

- Bid on remote projects competitors avoid (no nearby suppliers).

- Serve multiple job sites from one plant (90% setup time reduction).

- Client Example: A Saudi contractor won a desert highway bid by proving they’d bring the plant to the site.

Hidden Revenue Streams

- Monetize your plant during downtime by:

- Selling asphalt to local homebuilders (high-margin small batches).

- Leasing it to other contractors in off-seasons.

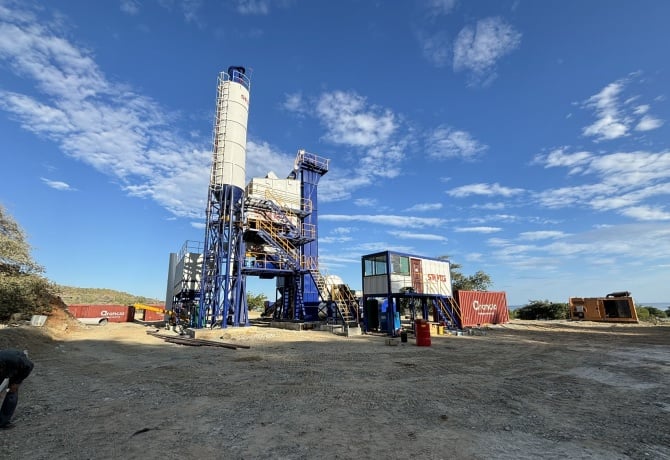

Lastest Success Story Spotlight: LB Series Asphalt Plant

As part of our commitment to Tanzania’s infrastructure growth, we’re proud to highlight our recently commissioned stationary asphalt station supporting the Tanzania city road upgrade project.

The Challenge

TANROADS faced mounting pressure to modernize Dar es Salaam’s congested road network, but:

- Supply bottlenecks: Reliance on distant asphalt suppliers caused delays (avg. 3-day wait for deliveries).

- Cost overruns: Transport fees added 18-25% to material costs.

- Quality inconsistencies: Variable mix grades led to premature road cracks.

Our Solution

In partnership with local contractor , we deployed a turnkey asphalt production hub featuring:

- Localized production: Plant installed within city limits, slashing transport costs by 95%.

- Tanzania-tailored specs: Modified mixes to withstand heavy monsoons and 40°C heat.

- Community-first design: Low-noise production (55 dB) and dust containment for urban areas.

Additional Benefits:

- ✓ Achieved 17% faster paving vs. conventional plants

- ✓ 98% emission compliance during TANESCO power outages

- ✓ Dedicated dust collection system meeting NEMC standards

A Message from Our Customer:

This plant became the backbone of our urban road strategy. We’re now completing 1.2 km of new roads weekly—something impossible with imported asphalt.

STLTG Asphalt Mixing Plant on Worksite

Top Construction Machinery Manufacturer in China

We specialize in manufacturing various types of construction machinery, including road machinery such as asphalt pavers, and road rollers, which are crucial for creating smooth and durable road surfaces. In the realm of lifting equipment, our cranes, both large-scale tower cranes for high-rise building projects and mobile cranes for more flexible operations, showcase our engineering prowess.

Our global footprint is remarkable. We have deployed engineers in multiple countries, including Tanzania, the Philippines, Indonesia, Algeria, Zimbabwe, Kenya, and Malaysia. These on-the-ground teams ensure that our customers receive prompt technical support, efficient installation, and comprehensive after-sales services. This local presence not only strengthens our relationship with clients but also allows us to better understand and adapt to the specific needs of different regional markets.

Quality is at the core of our operations. Sinotech Groups has obtained numerous industry-recognized certificates, which are a testament to our unwavering commitment to high – standards. Our factory is equipped with state-of-the-art facilities and adheres to strict manufacturing processes. With high-capacity production lines, we are capable of meeting large-scale orders in a timely manner without compromising on quality.

We cordially invite customers, partners, and industry enthusiasts to visit our factory. Experience firsthand the precision engineering, advanced manufacturing techniques, and the scale of our operations. At Sinotech Groups, we are not just a manufacturer; we are a reliable partner for all your construction machinery needs.

Our Factory:

Our 12,000-sqm dedicated storage facility operates under strict quality protocols, equipped with climate-controlled zones and automated inventory systems.

We maintain a rotating stock of 50+ machines in standardized configurations. Our pre-assembled units undergo final quality certification within 24 hours of order confirmation—ensuring same-week shipping for urgent projects.

Shipment:

With decades of engineering excellence and a commitment to premium quality, Our machines have earned the trust of construction professionals in over 80 countries worldwide. Our end-to-end operational expertise ensures every unit is delivered with precision.

Here, every machine undergoes triple-stage preparation:

- Pre-Shipment Optimization – Components are inspected, lubricated, and configured for seamless assembly at destination sites.

- ISO-Certified Packaging – Custom-engineered crates with shock-absorbent linings protect critical components, while waterproof sealing safeguards against maritime conditions.

- Smart Loading – GPS-tracked loading equipment positions cargo for optimal weight distribution, complying with international containerization standards.

Reliable Global Logistics

Partnering with tier-1 freight forwarders and maritime carriers, we guarantee trouble-free delivery:

- Door-to-Door Coordination – Real-time shipment tracking and customs clearance support

- Multimodal Flexibility – Tailored solutions for sea, air, or rail transport

Why Clients Trust STLTG:

- 30-year flawless delivery record with 99.7% on-time performance

- 24/7 multilingual logistics support team

- Pre-installation technical guidance sent 30 days prior to arrival

Our Certificate

We Provide The Best Service

Warranty

Equipment free warranty period of one year.

Fast Shipping

Prompt product shipping, home delivery.

Installation Guides

Engineer experts guide product installation.

Local Service

Local service network, timely wearing parts supply and service.

Customized Design

Support customized color, specification, capacity and so on.

Online Support

24 online for any help you need, we are always glad to be here for you.

Latest Projects

STLTG asphalt mixing plants are popular in countries such as South Africa, Australia, India, Argentina, Bolivia, Brazil, Chile, Colombia, Ecuador, French Guiana, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela, Kenya, Uganda, Tanzania, Nigeria, Syria, Lebanon, Iran, Israel, Egypt, Sudan, Libya, Indonesia, Laos, Malaysia, the Philippines, Singapore, Thailand, and Vietnam, among others.

STLTG LB1000 Asphalt Plant

Caracas, Venezuela

STLTG Mobile Asphalt Mixing Plant

Lagos, Nigeria

STLTG Continuous Drum Asphalt Mixing Plant

Khartoum, Sudan

STLTG LBQY60 Asphalt Plant

Jakarta, Indonesia

STLTG LB2000 Asphalt Plant

Quito, Ecuador

STLTG Continuous Drum Asphalt Mixing Plant

Montevideo, Uruguay

Not Sure Which One to Choose for Your Project?

INFORMATION

HAVE A QUESTION? CALL US

+86 18614956258

VISIT OUR COMPANY AT

Zhengzhou, Henan, China

SEND YOUR EMAIL

WORKING HOURS

24 Hours Online